Robotics is no longer a futuristic concept confined to science fiction; it's rapidly transforming industries from manufacturing and healthcare to logistics and even agriculture. This burgeoning field relies heavily on robust, efficient, and adaptable components, and at the heart of many robotic systems lies the DC gear motor. However, the evolution of robotics demands more than just traditional gear motors. New-generation DC gear motors, characterized by advancements in materials, control systems, and design, are paving the way for unprecedented capabilities and expanding applications. This article explores the innovative application trends driving the selection of these advanced motors, highlighting key benefits and future potential, especially in light of the current push towards automation and AI integration.

The accelerating adoption of Artificial Intelligence (AI) and Machine Learning (ML) in robotics is profoundly influencing motor selection. AI-powered robots require precise motion control, real-time adaptation, and increased responsiveness. This translates directly to demands on the motors – they must offer high torque density, accurate positioning, and efficient energy consumption to support complex algorithms.

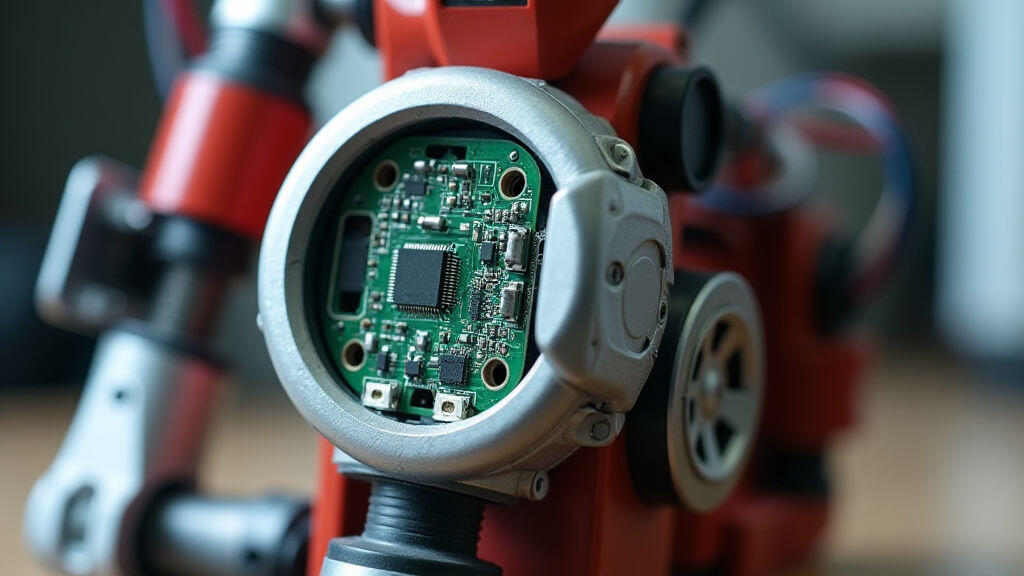

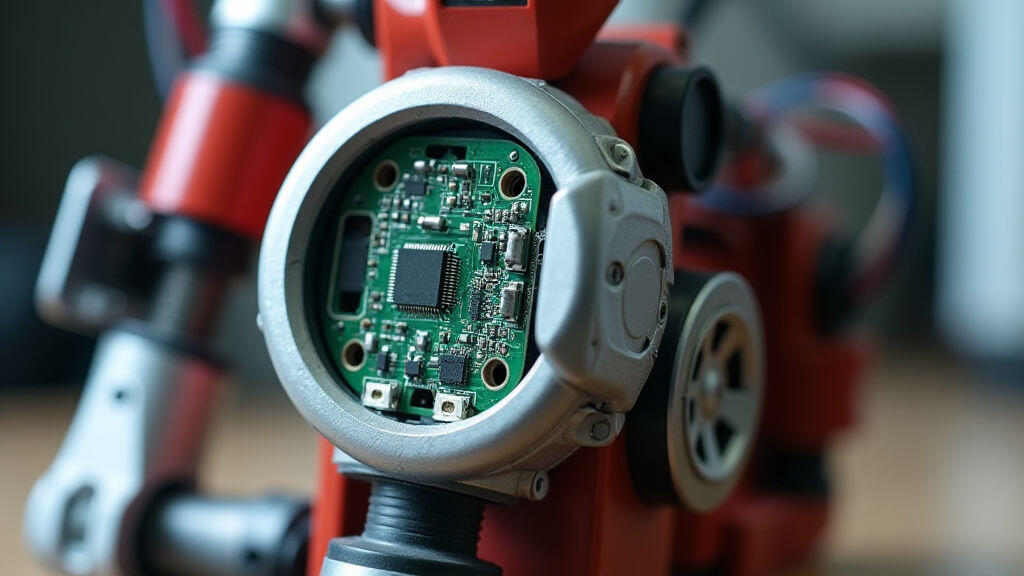

One key trend is the integration of embedded controllers within DC gear motors. This allows for decentralized control, reducing the need for bulky external electronics and simplifying system design.  This simplifies the integration process and allows for more flexible, adaptable robotic solutions. Furthermore, these integrated controllers enable advanced functionalities like closed-loop control, fault detection, and data logging – essential for AI-driven robots that need to learn and self-optimize.

This simplifies the integration process and allows for more flexible, adaptable robotic solutions. Furthermore, these integrated controllers enable advanced functionalities like closed-loop control, fault detection, and data logging – essential for AI-driven robots that need to learn and self-optimize.

Smaller, lighter, and more agile robots are becoming increasingly prevalent. This trend is fueled by applications like micro-robotics, wearable robotics, and drones. New-generation DC gear motors are specifically engineered to meet these demands, employing advanced materials like lightweight alloys and optimized gear designs to maximize power-to-weight ratios.

For instance, advancements in micro-manufacturing have spurred the development of tiny robotic arms for intricate tasks. These arms require highly compact motors offering high precision and low power consumption. MES-Drive offers a range of micro DC gear motors specifically designed for such applications, ensuring reliable performance in demanding environments. This miniaturization isn't just about size; it's about enabling robots to operate in previously inaccessible spaces and perform tasks requiring exceptional dexterity.

Sustainability is no longer a peripheral concern; it's a core business imperative. Energy efficiency is a paramount consideration in modern robotics, impacting operational costs and environmental footprint. New-generation DC gear motors boast significantly improved efficiency figures, often exceeding 90% under optimal operating conditions. This improvement stems from factors like optimized magnetic circuit design, reduced frictional losses, and the use of high-efficiency materials.

Moreover, sophisticated power management techniques are being integrated. These include regenerative braking systems that capture energy during deceleration and converters that optimize voltage and current delivery. This reduces energy waste and extends battery life – crucial for mobile robots and autonomous systems. The integration of power electronics further enhances the efficiency of the entire robotic system, leading to significant long-term cost savings.

Robotics applications are incredibly diverse, ranging from heavy-duty industrial machinery to delicate medical instruments. A one-size-fits-all approach to motor selection is no longer sufficient. The trend is towards customization and modularization, where motors can be tailored to specific application requirements.

MES-Drive is actively involved in offering configurable DC gear motors. Customers can choose from a variety of gear ratios, voltage options, and encoder resolutions to match the precise needs of their robotic system. Furthermore, modular designs allow for easy integration with other components and simplify maintenance. This flexibility enables engineers to optimize motor performance for specific tasks, maximizing efficiency and minimizing development time.

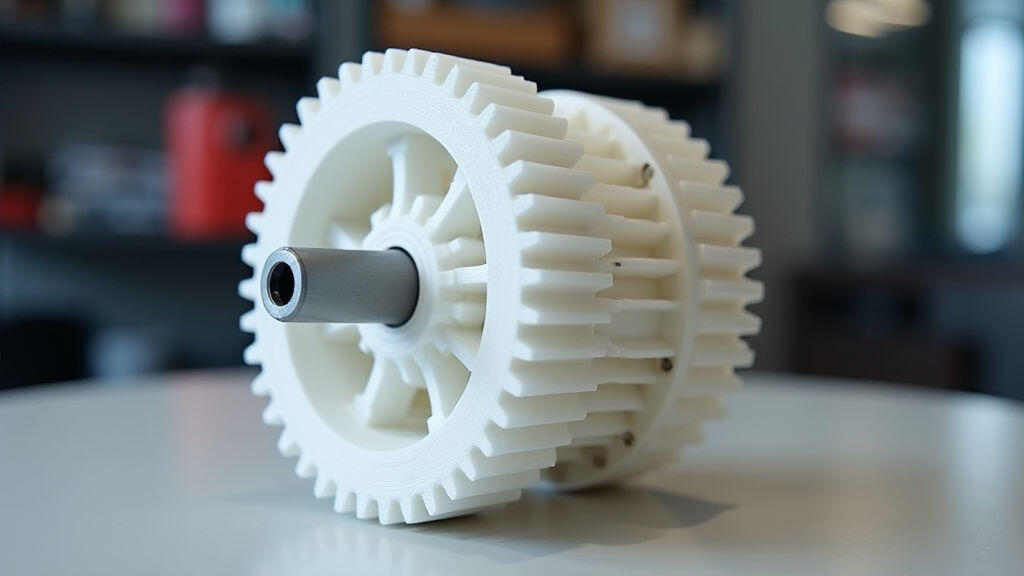

The selection of materials and manufacturing processes plays a crucial role in the performance and longevity of DC gear motors. New-generation motors are increasingly utilizing advanced materials like silicon steel laminations for reduced core losses, high-strength alloys for enhanced structural integrity, and specialized coatings for improved corrosion resistance.

Additive manufacturing (3D printing) is also gaining traction. This technology allows for the creation of complex geometries and customized components, enabling engineers to optimize motor designs for specific applications. For example, 3D printing can be used to create lightweight gear housings or integrate cooling channels for improved heat dissipation. This focus on materials and manufacturing is driving significant improvements in motor performance, reliability, and lifespan.

The advancements in DC gear motor technology are fueling innovation across a wide range of industries:

New-generation DC gear motors are revolutionizing robotics, enabling advanced capabilities, improved efficiency, and greater adaptability. The integration of AI, the demand for miniaturization, and the pressure for sustainability are driving innovation in motor design, materials, and control systems. MES-Drive, with its commitment to customization and advanced technologies, is at the forefront of this revolution.

As AI and automation continue to reshape industries, the demand for high-performance DC gear motors will only increase. Companies that embrace these innovative motor technologies will be best positioned to develop the next generation of robots and capitalize on the transformative potential of robotic solutions. The future of robotics is inextricably linked to the evolution of the DC gear motor, and the trends outlined here indicate a bright and exciting future.

Leave A Reply

Your email address will not be published. Required fiels are marked